Lean Six Sigma and Project Management - Are They Better Together?

- By Jessica Congemi

- •

- 02 Aug, 2018

According to the 2017 Global Project Management Survey Pulse of the Profession report, 12% of the global organizations studied, operating in a variety of industries from the government, to information technology, and financial services, were categorized as Under-performers.

Of the projects that failed,

- A lack of clearly defined or achievable milestones and objectives to measure progress was the primary contributor (37%)

- Within the federal government, only 64% of federal initiatives met their goals

- Government entities lost a staggering $101 million for every $1 billion spent on projects and programs according to a 2016 survey from the Project Management Institute (PMI)

For project managers, increasing productivity is an omnipresent goal. To reach this goal, it is essential to be aware of the vast array of methods and tools that have gained influence as best practices for planning, managing, and delivering projects. Although PMI has indicated an upward trend in completed projects globally, organizations can further benefit from removing waste and reducing variation through Lean Six Sigma practices in project management and execution. Alternatively, there is a benefit in applying project management principles to Lean Six Sigma projects to ensure successful completion as well. Across both frameworks, the idea is to follow a repeatable process aimed at creating successful outcomes. To better understand how integration is possible, it’s critical to define and baseline our understanding of both project management and Lean Six Sigma.

What is project management?

According to the PMI, project management is the application of knowledge, skills, tools, and techniques to project activities to meet project requirements. It is equally important to understand that a project is temporary in that it has a defined beginning and end in time, and therefore defined scope and resources.

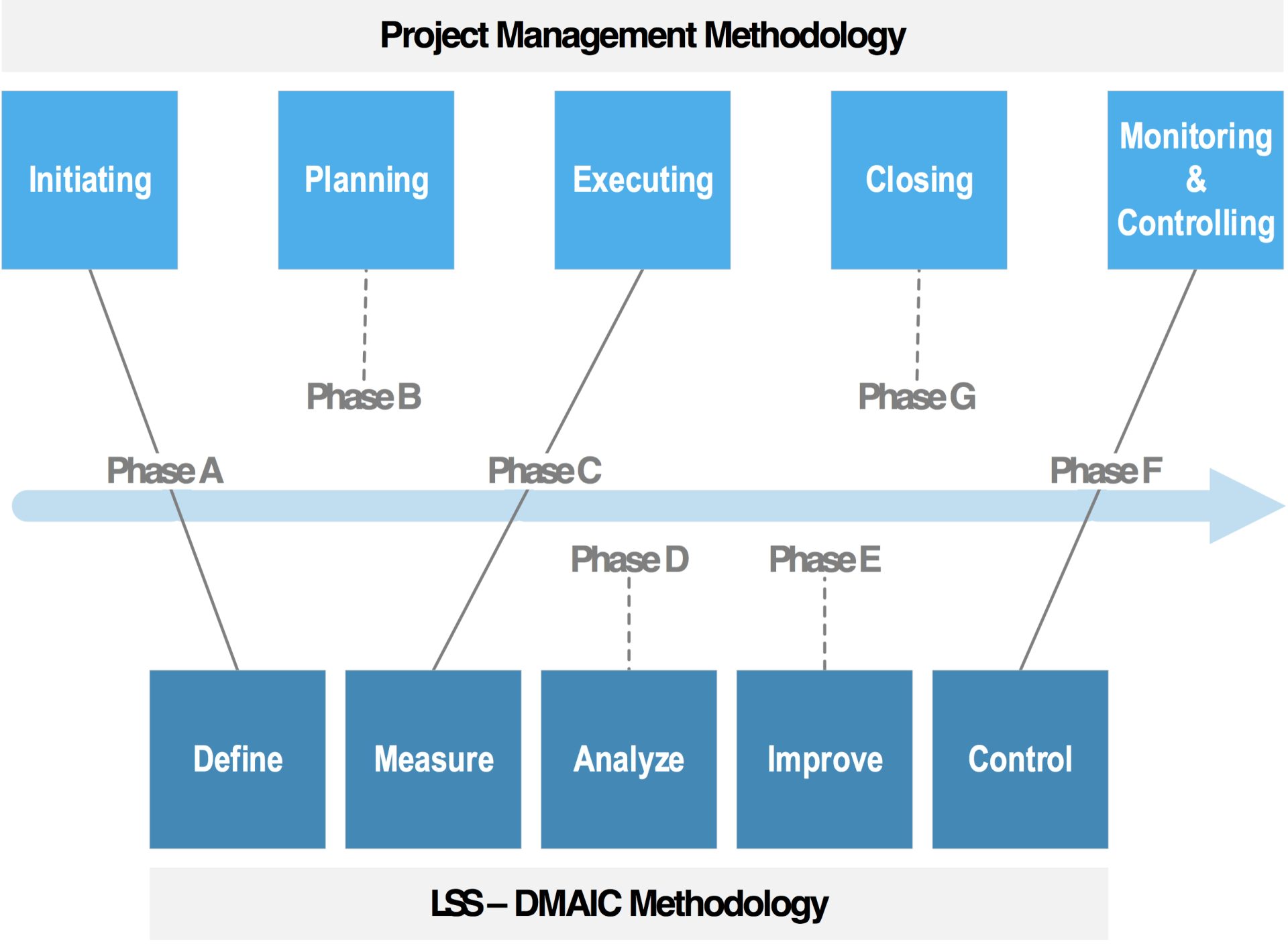

Project management processes fall into five groups: Initiating, Planning, Executing, Monitoring and Controlling, and Closing. Drawing on ten knowledge areas: Integration, Scope, Time, Cost, Quality, Procurement, Human resources, Communications, Risk management, and Stakeholder management, as visualized below:

On the surface, it’s logical that management within any organization would care about these aspects, but project management provides a specific focus to accomplish goals and objectives bound by budgets, schedules, and resources. Lean Six Sigma also offers a standard approach for achieving organizational goals and objectives.

What is Lean Six Sigma?

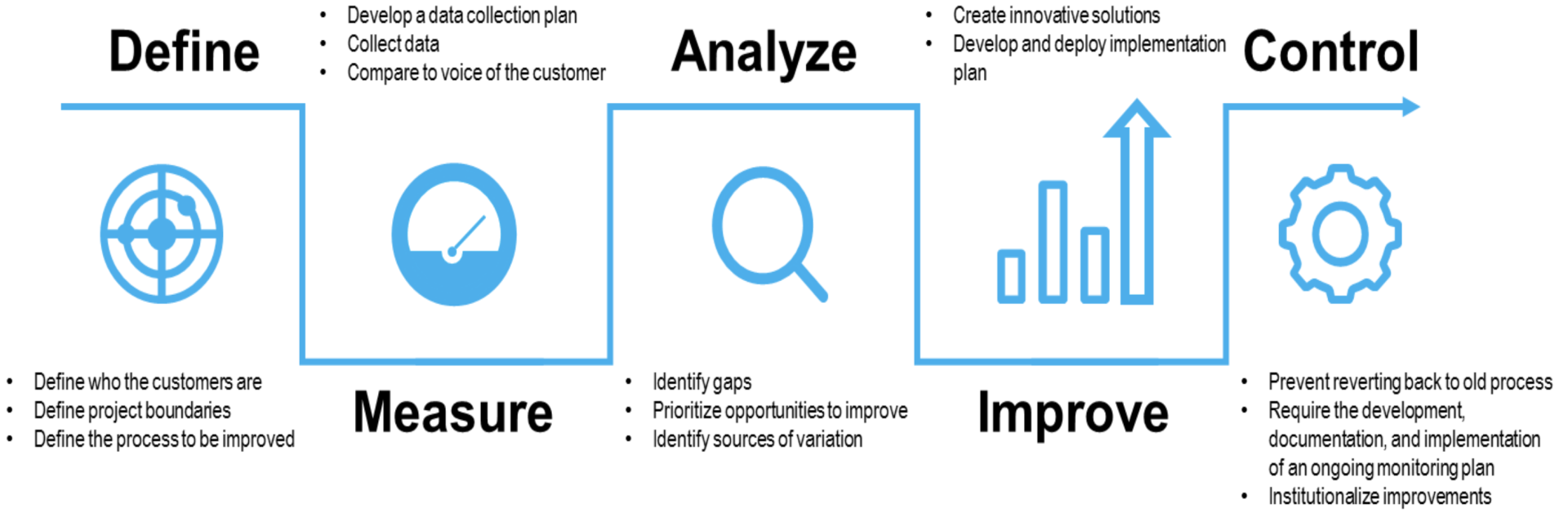

As defined by the American Society for Quality (ASQ), Lean Six Sigma is a fact-based, data-driven philosophy of improvement that values defect prevention over defect detection. It drives customer satisfaction and bottom-line results by reducing variation, waste, and cycle time while promoting the use of work standardization and flow, thereby creating a competitive advantage. It applies anywhere variation and waste exist. The DMAIC (Define, Measure, Analyze, Improve, and Control) methodology is most commonly used to execute Lean Six Sigma projects.

Successful users of Lean Sigma start with the lean approach, focusing on efficiency and effectiveness, reducing waste, and improving understanding. To dive deeper, Six Sigma statistical tools are applied to fix process problems further. In either case, strong management support is an organizational requirement for leveraging Lean Six Sigma. However, in the spirit of continuous improvement, there’s more that can be done.

Integration for better outcomes

Organizations across the globe can attest to the benefits of using a standardized approach to ensure successful project outcomes but can their effects be multiplied when used together?

The Six Sigma methodology DMAIC offers a structured and disciplined process for solving business problems. Its tools are used to identify root causes for the defects in processes that keep an organization from providing its customers with the consistent quality of products or services the customers require on time and at the most reasonable cost. Lean Six Sigma work is typically done through cross-function teams that manage the project. However, the methodology does not address the management of the project itself.

Project management’s tools and techniques focus on attributes of a project such as development, execution, control, and closing. There is an assortment of tools that are used throughout the project to manage the project to completion. Work breakdown analysis, schedule development, risk analysis, scope definition, status reporting and cost budgeting are common processes that project managers use to plan, execute, control and close projects.

Organically, Six Sigma Project Management Tools include project identification and selection methods, basic team development approaches, basic project planning and control tools, and post-project evaluation methods. However, there are challenges to confront when using Lean Six Sigma. An organization that relies solely on Lean Six Sigma to run its projects may experience issues with control of the project process. By taking the process control strength of project management and combining it with the troubleshooting strength of Six Sigma, an organization can create a consistent, controlled, and predictable process troubleshooting system. In fact, the project management approach, tools, and processes can be leveraged to complete a process improvement project. However, to leverage both approaches effectively, understanding the relationships between key elements is critical to realizing efficiencies between the two.

There is a strong relationship between scope and quality. Similarly, there is a solid relationship between time and cost. For example, a project can be completed faster for an additional expense. There is also a clear relationship between quality and cost. Poor quality increases total project cost due to rework and other failure costs. Indeed, there are strong relationships among various project parameters. We separate them to study and analyze each of them carefully while recognizing that each project parameter is related to other project parameters. Six Sigma tools used for measurement of the problem – Gage Repeatability and Reproducibility (R&R), Failure Modes and Effects Analysis (FMEA), and control plans – can be used within these project management areas. Throughout the project management lifecycle, these tools allow management to make informed decisions to move from phase to phase. The tools of both project management and Six Sigma can be placed in this lifecycle to plan, act, do, and check for a process improvement project. Additionally, the phases of both methods are related and can be blended for further enhancement. Specifically, the Lean Six Sigma DMAIC and project management methods can be integrated for project use as visualized below:

Common Pitfalls and Misconceptions

While there are tangible benefits of integrating Lean Six Sigma and project management methodologies, pitfalls and common misconceptions can still derail a project. Blending methodologies is not a one size fits all – the method should be aligned with the scope, complexity, budget, and timeline of the project. It’s up to project leaders and teams to determine which process and tools will best increase the probability of project success. Additionally, expectation management is key when using both frameworks together. In most instances, most new projects will not achieve Six Sigma level of performance – but it does set up high-quality standards and a mechanism to achieve project goals. Lastly, ensure the right resources are part of the project team to integrate and leverage tools from both frameworks. A team with no Lean Six Sigma or project management experience attempting to leverage tools from the lesser known method may ultimately result in frustration and abandoning the idea altogether.

Conclusion

Overall, integration of the two methods is achieved by combining the management aspects of project management and the data and analysis aspects of Lean Six Sigma. For organizations that only use project management within their system, Lean Six Sigma provides the enhanced ability to target customer needs and measure performance during project execution and monitoring using various technical and statistical tools. Additionally, the methodology of project management could benefit from the data and techniques of Lean Six Sigma in decision-making processes that promote a more evidence-based approach to factors that are critical to quality and for the customers.